Your cart is currently empty!

Seeking to boost your brand with custom pouches? This guide explores how tailored pouch packaging can enhance brand visibility and product protection. Learn about material choices, design strategies, and practical features designed to fit your specific needs. We provide practical insights for industries ranging from food to fashion, helping you make informed decisions for impactful packaging.

Table of Contents

- Key Takeaways

- Elevate Your Product Presentation with Custom Pouches

- Designing Your Unique Pouch Packaging

- Ensuring Quality and Compliance

- Tailored Solutions for Diverse Industries

- Maximizing Shelf Impact with Stand-Out Features

- From Concept to Completion: Your Custom Pouch Journey

- FAQS

- Summary

- Frequently Asked Questions

Key Takeaways

Branding Opportunities: Custom pouches provide significant branding and marketing opportunities through unique structure, versatile usage across various industries, and customizable features including size, closure options, and materials that enhance product protection and shelf life.

Accurate Fit to Portion Packaging: The design process of custom stand-up pouches demands careful consideration of brand identity, product specifications, and industry standards, including high-impact artwork, accurately sized packaging for optimal product fitting and display, and quality and compliance testing to ensure durability and safety.

Maximize Shelf Life: Custom pouches are designed to maximize shelf impact and consumer convenience with features like clear windows for product visibility, easy-open tear notches, and stable bottom gussets for upright presentation, as well as addressing the specific packaging regulations of food and non-food items.

Elevate Your Product Presentation with Custom Pouches

Custom-made Pouches offer a unique way of making your products stand out from the crowd. With their design, these pouches give products an upright position on shelves for higher visibility and to showcase top quality artwork that reinforces branding recognition. Not only can such stands be used as packaging but also as marketing tools when utilized properly with strong product presentation and brand promotion in mind.

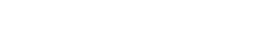

Customizable pouches have versatility across various applications like snacks, beverages, pet food items or even health supplements which makes them well suited for any kind of goods regardless of shape or size requirements – adjustable pouch sizing is available to create one’s own style perfectly fitting the needs of each particular item being packed inside it. You may opt for closure options such as zippers adding another layer customisation if desired by your brand standards.

In short: Custom Stand Up Pouch designs provide immense value far beyond just functioning solely as storage packs. They ultimately represent a chance to truly enhance levels upon how customers experience branded materials visually through artistry shown off while standing tall plus tactily thanks its customizable features catering to every single detail per individual requirement meeting all expectations – digital printing creates eye catching layouts defining aesthetics goal setting apart shelf presence distinctively thus creating long lasting memories staying at front minds potential buyers overall while watching steady increment sales won’t hurt either.

The Importance of Stand-Up Pouches

Stand-up pouches are a form of packaging that can stand up tall on shelves. These bags feature gussets at the bottom, enabling them to remain firmly upright and make products easily noticeable for customers. These packages offer great storage solutions due to their space efficiency as well as excellent product visibility when stored correctly.

Customization options also exist with regards to standing pouch designs – they come in many sizes fitting all kinds of goods from smaller single items through larger containers full of bulk item material such as granola bars or even premium coffee beans! No matter what type is being packaged up, there’s likely going to be an appropriate type of formatting outstandingly suited to it!

Material Matters: Barrier Films and Laminates

Custom packaging with white barrier film laminates and other materials offers protection for products, defending them against humidity, odors as well as oxidization to help enhance shelf life. Barrier films provide this service, especially when applied to pouches storing food items or liquids that need to remain in good condition throughout its usage time. The appropriate material selection depends largely on how long it needs to stay fresh – some popular options include metalized PET films plus recyclable ones while high-barrier varieties are very suitable for such tasks of preserving dryness and crispiness from foods over a longer duration. All these custom materials ensure maximum satisfaction among customers due to their efficient maintenance capabilities required by both consumers and producers alike.

Customization Options Galore

Custom pouches offer a great range of personalization options for brands. From pouch size to material type and design, each flat pouch bag can be customized with ease according to the product’s requirements. You could choose from different types such as Standard Zipper or Fine Powder Zipper closures. To various hang hole positions for better display purposes along with tear notches if needed.

In terms of materials available, Gloss Laminate, Matte Laminate Clear and Kraft Laminates are among some popular choices that customers may opt-in depending on their preferences. Metallic effects and even compostable alternatives also exist out there within this selection too!

The bottom line is that customizing your brand’s own unique piece bags by getting creative when it comes to choosing suitable sizes down picking appropriate flexible materials while making sure all important functional features like holes (hang/tear) and zippers have been taken into consideration first might just prove itself very rewarding at the end, giving you premium quality look without compromising either aesthetics nor practicality matters afterwards!

Designing Your Unique Pouch Packaging

When designing custom pouch packaging, it’s essential to have a detailed understanding of your brand identity as well as product needs and industry regulations. Establishing visually stimulating artwork is paramount when creating the design, which also includes appropriate logo usage and an exact color palette. Following this step involves assessing important factors such as size, shape, weight and shelf life in order to ensure that the end result successfully safeguards while maximizing product presentation potentials. The last part is ensuring high quality standards for excellent protection are met plus all necessary regulations adhered too – with careful attention being paid to dimensions (for accuracy), suitable materials for durability along with distinctive visual characteristics from what was established by those representing your brand!

Artwork and Branding

When it comes to custom pouches, artwork plays an essential role in the success of their packaging. Vibrant colors and graphics that draw consumer attention plus providing pertinent product information are all necessary for creating effective pouch designs. Branding is also vital – logos, color schemes, typography, and other visual components must be incorporated into your design while still adhering to brand guidelines. This will build recognition and trust with shoppers. All these elements coming together can make or break a package’s impact on consumers’ purchasing decisions when selecting among different pouches available for sale.

Choosing the Right Size and Features

The selection of an appropriate pouch size is essential to ensure your product’s optimal functionality and appeal. Dimensions, such as width, height and gusset should be taken into account along with any insulation requirements or fittings for stability. Custom pouches are available in a range of sizes ranging from 6×8 up to 14×24 inches but can also be altered if needed so that whatever you need packaging wise, the correct sized pouch will have been designed with your goods in mind. Whether it’s small single-serving items being packaged or bulkier objects, there is most certainly a customised option perfect for whatever task lies at hand!

Ensuring Quality and Compliance

Quality control and compliance with industry regulations is a vital component in pouch packaging design. It’s not only about creating aesthetically pleasing pouches, it also needs to guarantee the safety of whatever product they may contain.

To ensure high-quality custom packagings are produced, various tests must be conducted such as Edge Crush Test (ECT), Bursting Strength Test (BST), Puncture Resistance Testing, Food Packaging Tests, Tensile Analysis and Heat Sealer examination. With these standards kept in mind, any customized package can stay strong yet still look attractive while safely containing its contents.

Tailored Solutions for Diverse Industries

The versatility of custom pouches makes them an attractive choice for a wide range of industries. From food products to non-food items, these special packages offer tailored solutions that meet all types of packaging requirements. Custom pouch packing offers several notable advantages like elevated brand recognition, trust building among customers and flexible printing options, making it the preferred option in many food businesses. The resealable feature also allows multiple openings while still providing product protection and extension shelf life as well as cost efficiency when transporting goods. Non-food industry operators can also benefit from this type of custom packaging due to its lightweight yet effective nature. Facilitating easy storage with economical printing choices offering convenience during transportation too.

Food Industry Packaging

Packaging in the food industry is a critical component of product safety, as outlined by rules and regulations from Title 21’s C.F.R. on Food and Drugs (Part 176-186). As such, it must be carefully chosen to ensure maximum freshness and quality for all foods packaged within it. Some materials used include plastics, glass, metals ceramic paper/board printing inks wax wood, each possessing its own unique advantages that should weigh into selection decisions depending upon individual product needs. Knowing how important both packaging material choices are to maintaining premium food products means they should not be overlooked or underestimated at any cost!

Non-Food Product Packaging

Custom pouches are incredibly beneficial when it comes to packaging non-food items. These sealable and durable products offer a layer of protection from the elements like humidity or air that can threaten product quality. They make opening and storing easier for consumers, allowing them to access their goods multiple times while ensuring extended shelf life at the same time improving overall user experience. This custom type of pouch also creates an extra barrier so food remains in prime condition as well as enhancing its longevity on shelves everywhere.

Maximizing Shelf Impact with Stand-Out Features

Once custom pouches have been crafted and finalized, the next step is devising how to exhibit them in stores. Without proper shelf display, even a well-made pouch won’t stand out or be easy for consumers to access. Transparent packaging can increase item visibility by providing potential customers with an unobstructed view of what’s inside – improving product attention, introducing visual interest, upping brand presence as well as demonstrating freshness through visuals. Plus, adding tear notches like single ones ensures user friendliness since they let individuals easily open bags at just a simple pull and rip motion.

Visibility and Accessibility

Custom pouches are increasingly designed to enable accessibility and inclusivity. Transparent windows help attract customers, providing a clear view of the product for sale. Innovative packaging features have been identified as invaluable tools which allow individuals with varying impairments easy access to essential information – from braille labels for those who can’t see, openable packages suited to people with limited dexterity or high-contrasted versions catered towards low vision conditions right through to simple instructions made understandable by cognitive disability sufferers. Stand up pouches incorporate these design principles that appeal more broadly to potential buyers in order to make their products visible and accessible on market shelves everywhere!

Stability and Display

Custom pouches with stable bottom gussets play a critical role in their overall display and appeal. With such a design, the pouch can stand up straight on shelves to create an attractive presentation that shows off its contents more effectively than if it were unsteady. Incorporating this feature into custom pouch packaging also ensures capacity is maintained without needing extra shelf space. A strong base created by bottom gusseting enables the bag to keep shape while minimizing any risk of tipping over as well as improving its consumer attractiveness levels.

From Concept to Completion: Your Custom Pouch Journey

Creating a custom pouch involves more than just design. The following steps are essential to complete the process and bring your vision into fruition: selecting suitable pouch options, completing final artwork designs, and placing an order for production.

To make sure that all requirements of your product are met, it is important to consider carefully when choosing size, material and any other features you wish to include in the package.

Finalizing your packaging artwork requires precision – providing manufacturers with accurate details such as dimensions or materials used must be done during pre-press before ordering production runs so that everything looks exactly as planned upon completion!

Selecting Your Pouch Options

When choosing the most suitable pouch solutions for your product, there are a few factors to take into consideration. These include things like material type and size of each individual pouch as well as any unique needs that may be specific to your item or items being packaged. Stand-up pouches come in varied sizes from mini 3×5 inch bags through larger 6×8 inches up until 14×24 – all offering something different depending on what it is you’re looking for when making them customised pieces. Options such as aluminum foil, polythene/polyester mix. Pure aluminum coatings plus microfiber, PU leather and also linen woven with canvas or satin fabric styles too!

Finalizing Your Design

Once the pouch options have been chosen, you must complete your design. It is necessary to make sure that it abides by industry regulations, such as using CMYK format for colored artwork and grayscale format when dealing with black-and-white illustrations.

Building a custom pouch encompasses more than just making it look nice. Every single detail should work together in order to optimize its efficiency. Dimensions and materials are just some of the factors that need careful consideration along with features and stylistic elements, all these play an essential role in creating effective pouches!

Placing Your Order and Production

When the design is ready, it’s time to make a purchase. The process begins with choosing an appropriate pouch supplier and giving them your finished plans along with exact details of what you need. It’s important that the chosen manufacturer can bring your vision into reality while producing top quality pouches according to specified standards.

The production timeline for customized containers includes obtaining suitable materials and putting together and packaging everything in place which usually takes anywhere from several days up to twelve weeks depending on order particulars.

FAQS

When ordering custom pouches, the minimum order quantity is usually 100 units. To ensure artwork complies with industry standards, use CMYK for full-colour and greyscale for black & white images. There are various features such as zippers or tear notches that can be included to meet individual needs. When selecting a size, make sure your product plus 0.25 inches per dimension fits in it correctly. The production timeline varies depending on specifications from several days up to twelve weeks typically.

Summary

Custom pouches are an excellent packaging solution due to their highly customizable structure, material range and size options. They provide tailored solutions for a variety of products in different industries – be it food related or not. Not only do these unique pouches help create better product presentation, but also heighten brand recognition while enhancing the safety of goods as well as consumer satisfaction with the final result.

Frequently Asked Questions

Why use pouch packaging?

Pouches provide a great solution for packaging food, offering superior protection against external factors such as moisture, contaminants and UV rays. These are also lightweight and easy to store making them ideal in terms of reducing the environmental impact from their production right up through distribution. Pouch packaging can keep edibles fresh longer due to its puncture-resistant films, which offer an extra level of security throughout transportation.

What is a pouch bag?

A pouch bag is a type of container, ranging from small enough to be worn on the body to moderate in size for holding items. Such an item can also describe particular anatomical structures located within some creatures.

Is pouch packaging recyclable?

Many supermarkets and grocery stores accept recycling of clean, dry PE pouches for disposal. Inquire with your local store to determine drop-off points.

What size is a stand up pouch design?

Stand up pouch sizes come in a variety of standard options, ranging from 6×8 to 14×24 inches. Custom sizing is also available for those looking for specific dimensions with their pouches.

What is the minimum order quantity for packaging pouches?

For smaller businesses with limited quantity requirements, purchasing packaging pouches is easy – it only requires a minimum of 100 units.